The coal industry has a serious impact on the development of other sectors of the world economy – primarily railway and sea transport, electric power, housing and utility sector, heavy and transport engineering, metallurgical industry.

It is difficult to overestimate the strategic advantages of enterprises with an established and uninterrupted supply of energy sources to the production process. Taking into account the constant reduction of the world reserves of “black gold”, its rational consumption and maximum output on use is increasingly becoming one of the main tasks of both private and public managers.

Coal mining and processing enterprises are striving to minimize the costs of mining, transporting, storing and processing of coal. Interruptions in its supply affect not only the economic performance of individual regions, but also directly on their population – in many localities, coal provides up to 50% of heat and electricity generation.

The key to success is the use of reliable innovative technologies that permit achievement the record results, and then broadcast and scale them to all the enterprises in the industry. One of the brightest examples is undoubtedly the technology of magnetic-impulse cleaning of hoppers based on the installations IM manufactured by RPE “MITEK” LLC.

Magnetic-impulse installations IM have become a traditional tool for ensuring uninterrupted and timely supply of solid fuel at many enterprises, including: mining and processing plants, fuel and energy complexes, metallurgical complexes (see the list of implementations of installations IM in this industry).

At the coal facilities, the following types of magnetic-impulse installations IM have found the greatest use: IM3-1,5-n, IM3-1,9-n, IM4-1,8-n (where n is the number of installation channels – two executive mechanisms per each channel).

Among the numerous coal facilities equipped with installations IM, the following should be highlighted:

- receiving, accumulating, intermediate, dosing, consumable hoppers,

- hoppers under the railcar dumpers and the car dumpers themselves,

- coal storage silos and hopper racks,

- dust collecting towers and cyclones,

- cargo handling units and chutes,

- injection systems of pulverized coal,

- lots of others.

A wide range of energy parameters of magnetic-impulse installations IM allows specialists of RPE “MITEK” LLLC to most precisely determine the optimal type of installation IM for a particular facility, taking into account its technical characteristics and Consumer requirements.

The wealth of practice in use of magnetic-impulse systems of our production actually proves its superiority in comparison with the previously widely used pneumatic and vibration devices, and, moreover, manual cleaning. The positive feedbacks from Consumers, as well as numerous repeated orders of our equipment, testify to the higher efficiency, reliability, and safety of installations IM.

Examples of schemes for equipping the various production facilities with the installations IM

Closed coal warehouses

The design of a closed coal warehouse usually consists of a line of twin reinforced concrete silos with a metal cone part, in each group of which the bulk material of various characteristics is stored. Dosing conveyors or feeders supply the material to the collecting conveyor. In this case, the exact dosing of each component and their layered mixing must be observed, that enables obtaining the mixtures of a given composition.

Violation of the timely supply of any of the components onto the assembly line leads to a forced stop of the line. The possible reasons for arching and hanging of materials are:

- the design features of silos and funnels,

- low temperatures for high-moisture material,

- significant compaction of the material when falling during loading of silos,

- adhesion properties and instability of other physical and mechanical characteristics.

To solve these problems, manual labor is often engaged using the sledgehammers or more powerful percussion tools, that leads to such consequences as:

- deformation of the walls, where even more complex hangings of materials are formed,

- destruction of welded joints and bases of fastenings of the entire structure of the hopper,

- frequent injuries to service personnel.

In addition to the low efficiency of this method of arches collapsing, one has to put up with the frequent shutdowns of prosessing lines for unscheduled repairs.

Until recent times, the electric vibrators and pneumatic impulse systems were considered as the traditional mechanical systems for elimination of hanging.

- The electric vibrators are short-lived, often lead to the destruction of the walls of hoppers, to the compaction of the material in the hopper.

- The pneumatic systems require the generation and preparation (drying) of high pressure air, and are inefficient in case of material freezing.

Since the beginning of the 90s, in order to eliminate the hang-ups of bulk materials, electric vibrators and pneumatic systems have been replaced by efficient and economical in operation the magnetic-impulse installations IM manufactured by RPE “MITEK” LLC. They have a number of advantages compared to their predecessors, namely:

- possibility of prompt adjustment of the amplitude, shape and repetition rate of the acting impulses;

- possibility of not only collapsing the suspended material, but also cleaning the surface (hopper wall) from adhering material;

- work in energy-saving mode with minimal operating costs;

- preservation of the integrity of the cleaned walls of hoppers and other surfaces;

- ease of operation, maintainability, durability. The service life of IM installations before the overhaul is at least 10 years.

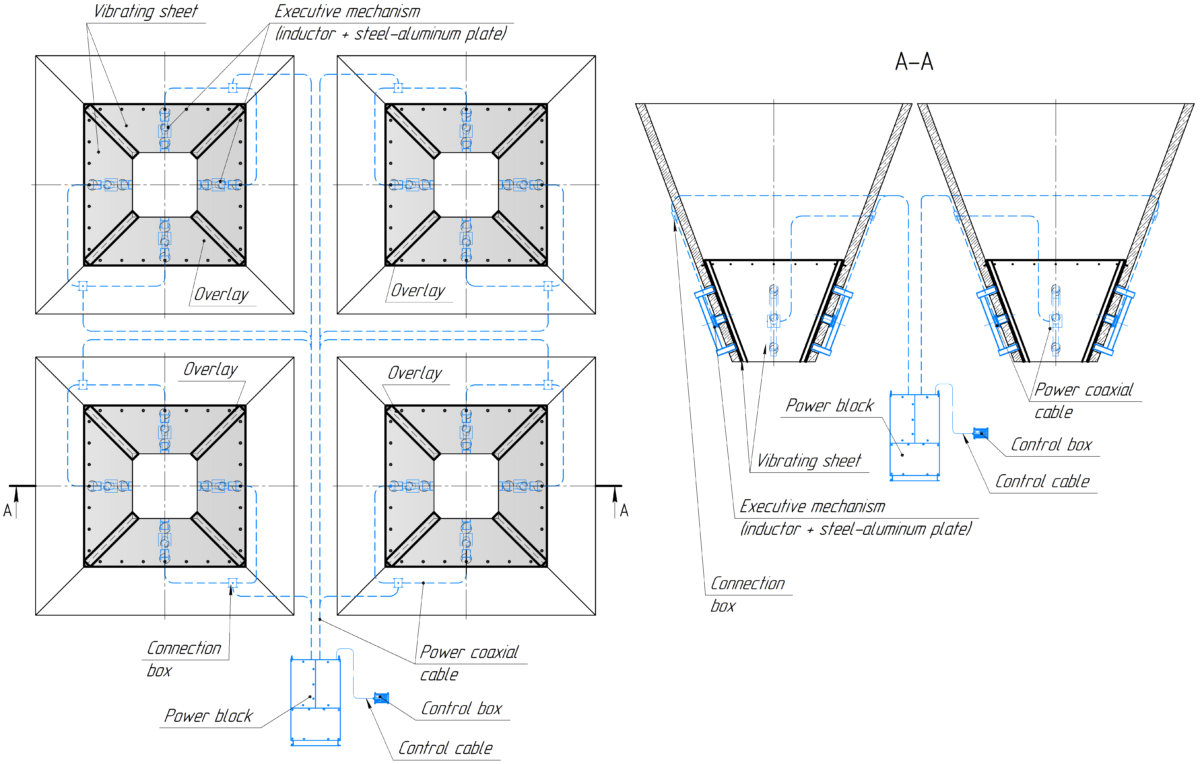

As an example, below is a diagram of equipping 28 silos of a closed coal warehouse of the coal preparation workshop of CP:

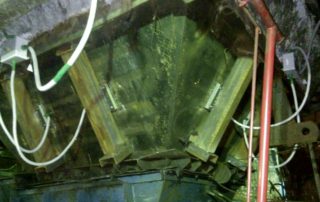

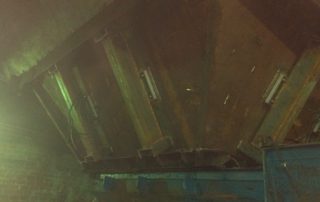

Photos of equipping silos of coal warehouses with the installations IM:

Receiving hoppers under railcar dumpers

In general, the planned unloading capacity of railcar dumpers is up to 30 railcars per hour. It should not take more than 2-3 minutes to unload each railcar. The ensuring of sufficient throughput and unloading speed of receiving hoppers is a fundamental task, on which the main performance indicators depend.

Hoppers must withstand the load of material falling from the height of 15-20 m, which is supplied in large volumes (up to 150 tons). Therefore, they are made of thick-walled and rigid-ribbed structures, lined with armor plates. The material, fed into them is of different dispersion, wet, and often frozen.

The most efficient and reliable way to eliminate the hanging of materials in the hoppers under the railcar dumpers is the use of magnetic-impulse cleaning systems. None of the known alternative methods can compete with the installations IM manufactured by RPE “MITEK” LLC.

This is evidenced by the numerous successful implementations of magnetic-impulse installations IM on hoppers under railcar dumpers.

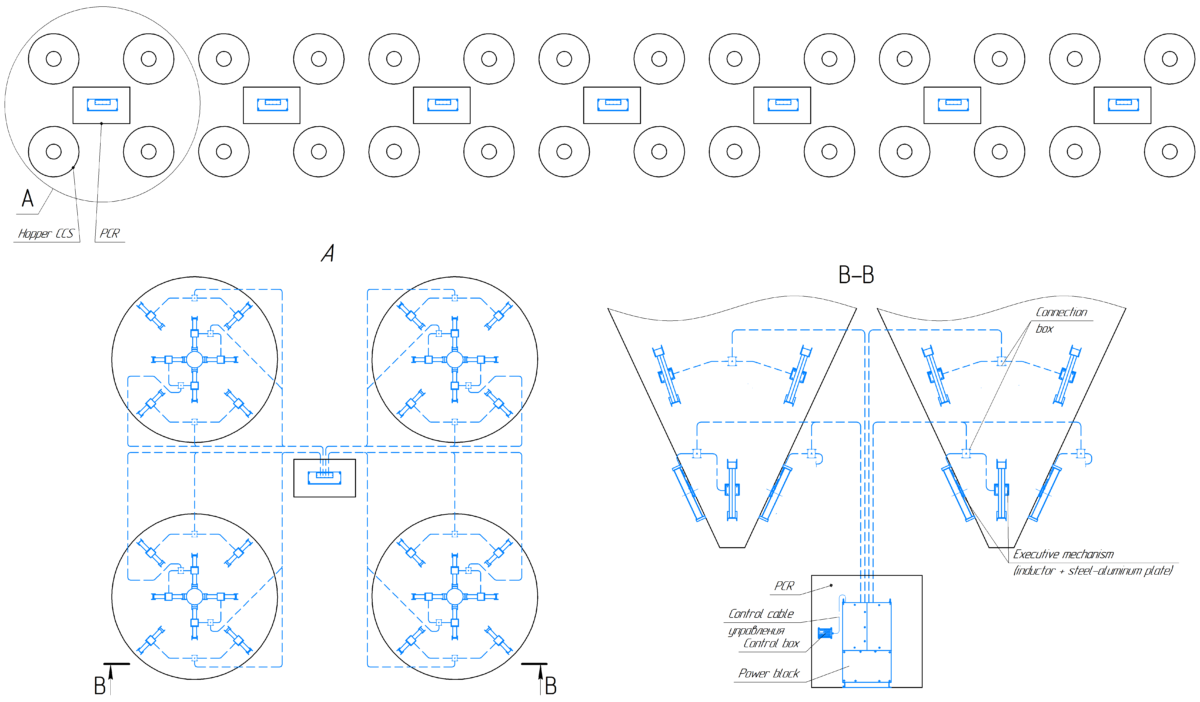

Here is a scheme of equipping hoppers under two railcar dumpers of coke production:

Implementations map

Magnetic-impulse installations IM:

- ensure a sustainable release of material from equipped hoppers;

- clean the walls of hoppers from adhered material;

- provide efficient filter regeneration;

- operation in an energy-saving mode, operating costs are minimal;

- basically do not require reconstruction of hoppers when equipping them;

- do not violate the integrity of the walls of the hoppers;

- compatible with strain gauge systems for controlling the weight of material in hoppers;

- comply with the requirements of the Directives and harmonized technical regulation of the European Union on electrical safety and electromagnetic compatibility;

- applicable in hazardous areas of class 22, hazardous by ignition of combustible dust in accordance with the ATEX Directive;

- easily integrated into modern automated process control systems;

- reliable and durable (according to technical conditions – 10 years, in practice, some installations have already been in operation for more than 25 years).