Various systems for shaking hoses and electrodes are used to regenerate the bag filters.

Traditional shaking systems are:

- mechanical system for electric and bag filters – constitutes a complex mechanism in operation, consisting of shafts, worm gears, cams, couplings, levers, etc., in most cases, it does not allow to quickly adjust the force and frequency of impact on the treated hoses of bag filters and electrodes;

- pneumatic impulse system for bag filters. This system requires the generation of high pressure air and its special preparation (for example, drying).

Magnetic-impulse installations IM are successfully used in gas cleaning systems both for eliminating dust hanging in various hoppers and cyclones, and for shaking the hoses and electrodes of bag filters and electic precipitators in order to regenerate them.

Installations IM are more efficient, durable and economical in operation in comparison to the above-mentioned traditional shaking and cleaning systems owing to the following factors:

- use of energy-saving technology;

- integrity of the structures of the surfaces to be cleaned is maintained;

- ability to quickly adjust the impulse force, amplitude, shape, repetition rate of the impulses;

- high efficiency, reliability and ease of maintenance;

- simplicity in operation, repairability and durability – the service life of IM installations before overhaul is at least 10 years.

Use of magnetic-impulse installations IM for regeneration of hoses of bag filters

There is a technical solution for bag filter regeneration patented by the specialists of RPE “MITEK” LLC (patent of Ukraine № 37191).

To regenerate the bag filter, the power block generates a powerful current impulse into the inductor winding, then a force arises that pushes the inductor and the steel-aluminum plate apart. The steel-aluminum plate is repelled from the stationary inductor and sets in motion the traverse with the arms suspended from it. As a result of this action, the arms are stretched “in the impulse mode”, and after the return of the traverse to its initial position, they take their initial condition. At the same time, the dust particles are released from the fabric and, under the action of gravity, fall into the hopper.

The efficiency of bag filter regeneration depends on the fact whether the acceleration reaches a level sufficient to detach the dust layer from the filter surface when shaking the hoses of bag filter. Only the use of magnetic-impulse regeneration enables variation of acceleration to a large extent, achieving cleaning of the filtering cloth.

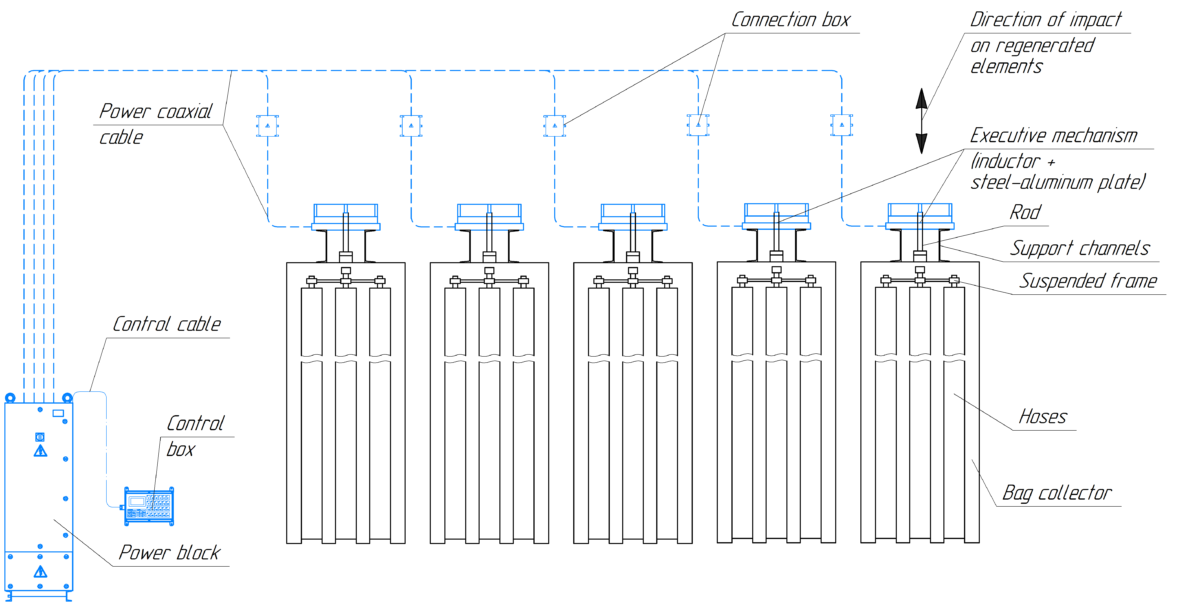

Scheme of equipping the bag filter with a magnetic-impulse regeneration system based on the IM installation:

In this case, installations of the IM3-1,1-n type are applicable, where n is the number of channels from 1 to 16, one or two executive mechanisms in the channel.

Several bag filters in the cities of Kryvyi Rih and Armians’k are equipped with magnetic-impulse installations IM. Feedback on the use of installations IM and photos are available in the “Gas cleaning” section.

Use of magnetic-impulse installations IM for regeneration of electric precipitators’ fields

There is a technical solution for the regeneration of an electric precipitator patented by the specialists of RPE “MITEK” LLC (patent of Ukraine № 37190).

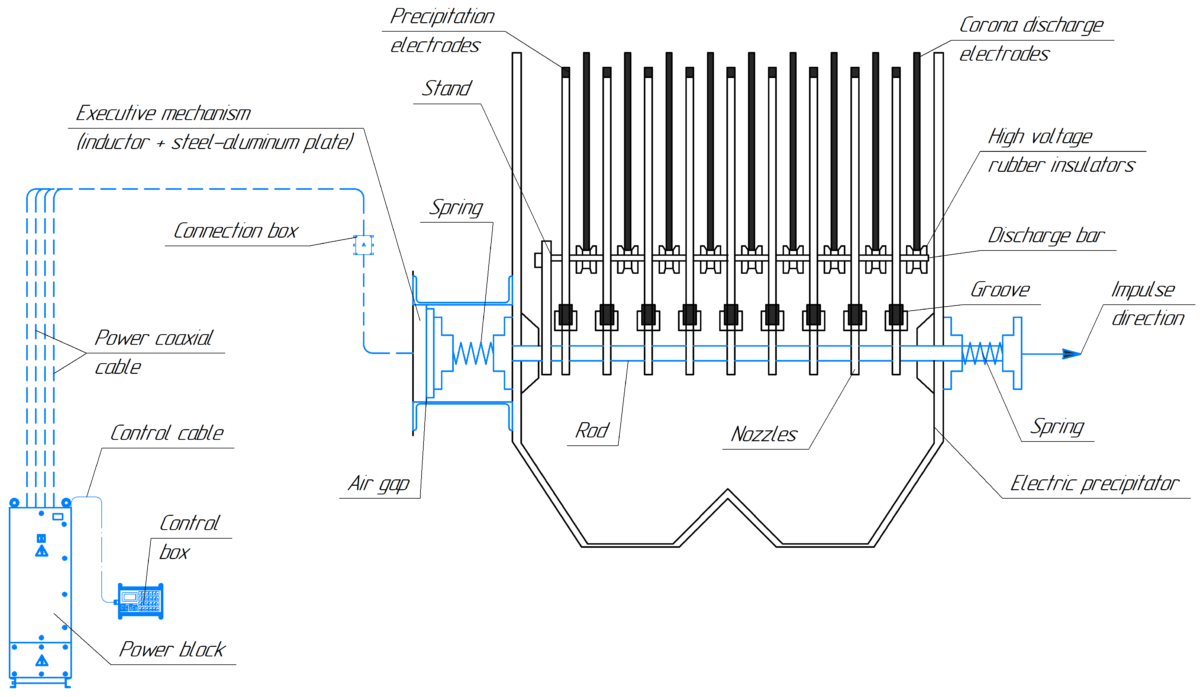

To regenerate the electric precipitator, the power block generates a powerful current impulse into the winding of the stationary inductor. Thus a force arises that pushes the steel-aluminum plate away from the inductor, and leads to a longitudinal movement of the thrust. The nozzles available on the thrust act on the collecting electrodes, and the rod attached to the thrust in a special way acts on discharge electrodes that leads to cleaning the surface of the electrodes from the dust deposited on them.

The executive mechanisms of the IM installation create a controlled impulse effect on the movable thrust and rods, which shake the collecting and corona electrodes.

Electric precipitator regeneration system based on the magnetic-impulse installation IM:

Installations of the IM3-1,1-n type are applied, where n is the number of channels corresponding to the number of processed fields of electric precipitator.

At present moment, there are no industrial implementations of installations IM for the regeneration of electric precipitators, despite a successful technical solution. The project on the use of magnetic-impulse installations IM for regeneration of electric precipitators is in the process of being finalized and improved. At the same time, there are positive results of the experimental industrial operation of an experimental model of system based on the installation IM at one of the electric precipitators of Tripolskaya TPP.

At your request we are ready to offer the development of designs for electrode shaking systems based on installations IM with reference to specific electric precipitators. We invite all the interested parties to cooperate on this topic.

The detailed information on the use of installations IM in the gas cleaning systems with reviews on the use and photos are available in the gas cleaning section.

We are always glad to receive your orders!