The geography of the implementation of magnetic-impulse installations IM stretches from the Southern plains of the Kazakh steppes to the frozen rocks and soils of the Far North, from the Far Eastern Okhotsk coast to the warm Black Sea coast. They were used everywhere and always the qualities and advantages of our systems were appreciated:

- in a matter of days, the gold miners recoup the costs of introducing installations IM and note the complete absence of downtime of production lines due to clogging of hoppers and, as a result, an increase in planned performance indicators by 10% as a result of our equipment use;

- concentrator engineers note the high efficiency and reliability of magnetic-impulse cleaning systems even with an increase in material moisture content up to 35%, as well as steady operation of installations IM and assured elimination of the loaded material freezing at temperatures down to -45°C;

- coal miners focus on energy efficiency – electricity consumption of about 0.2 kW/h, that is by several orders more economical than using hopper heating devices and the use of electrical and pneumatic systems, while the magnetic-impulse technology is more efficient compared to them

We invite you to read the other reviews, as well as video reviews of ore mining and processing specialists:

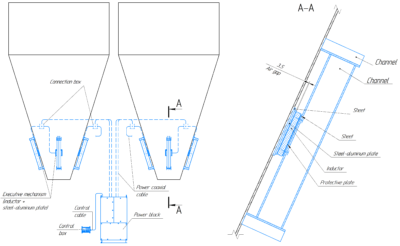

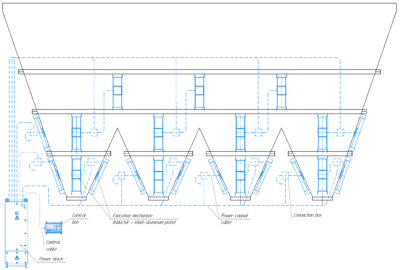

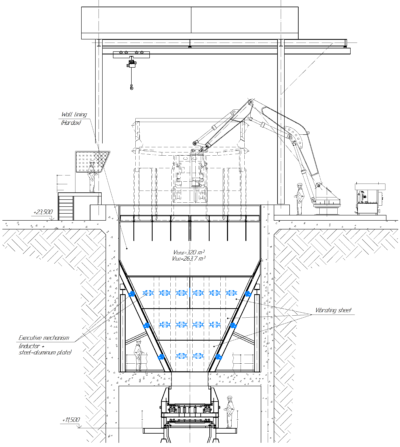

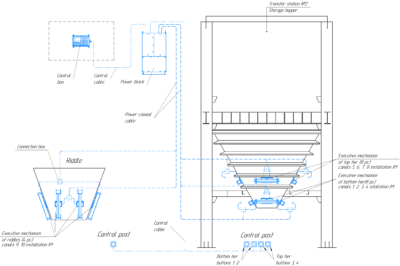

The most difficult with respect to eliminating the hanging of bulk materials are the receiving hoppers of rocks and ores. They are frequently thick-walled and rigidly ribbed structures, lined with armoured plates, and the material fed into them is heterogeneous, wet, sometimes frozen. At the same time, the assured release of material from the receiving hoppers is a task of paramount importance, aimed at preventing downtime of production lines.

Since 1998, RPE “MITEK” LLC has been confidently solving this problem at various mining and processing plants, equipping receiving hoppers with magnetic-impulse installations IM.

There are enterprises where hoppers, silos and chutes of the entire production line are equipped with installations IM, starting from receiving hoppers and ending with finished product hoppers, for example, CF Kaskad-2 Vinogradovsky open pit mine is a branch of PJSC Kuzbass Fuel Company.

From a multitude of the facilities equipped with installations IM in the mining and processing industry, in addition to receiving hoppers, the following can be distinguished:

- hoppers under railcar dumpers;

- accumulating and storage hoppers;

- dosing hoppers;

- surge plates and loading trays;

- cargo handling units;

- finished product hoppers;

- loading hoppers;

- overflow chutes.

We offer you to learn about the list of implementations of installations IM in this industry. For the mentioned objects, the high-energy installations of the type IM4, IM5 with a stored energy of about 20 kJ are mainly used.

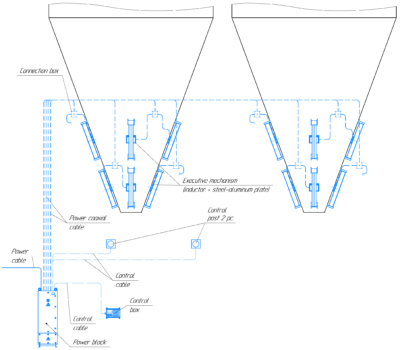

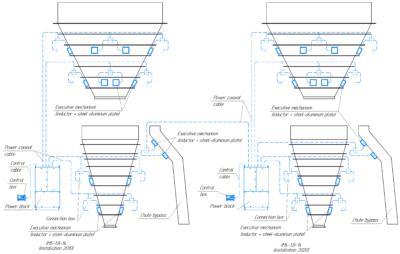

Examples of equipping some production facilities with installations IM

Implementations map

Magnetic-impulse installations IM:

- ensure a sustainable release of material from equipped hoppers;

- clean the walls of hoppers from adhered material;

- provide efficient filter regeneration;

- operation in an energy-saving mode, operating costs are minimal;

- basically do not require reconstruction of hoppers when equipping them;

- do not violate the integrity of the walls of the hoppers;

- compatible with strain gauge systems for controlling the weight of material in hoppers;

- comply with the requirements of the Directives and harmonized technical regulation of the European Union on electrical safety and electromagnetic compatibility;

- applicable in hazardous areas of class 22, hazardous by ignition of combustible dust in accordance with the ATEX Directive;

- easily integrated into modern automated process control systems;

- reliable and durable (according to technical conditions – 10 years, in practice, some installations have already been in operation for more than 25 years).