The development of converter steel production follows the path of increasing the unitary capacity of converters with a simultaneous increase in the operating intensification. With an increase in the capacity of converters, the technical and economic indicators of production are being improved.

For the operation of large-capacity converters, in addition to solving other problems, it is required to ensure uninterrupted supply and loading of bulk slag forming materials into them, burnt lime, as well as dosing and supply of ferroalloys.

In the chain for feeding bulk materials into the converter, the following types of hoppers are present:

- receiving;

- supply;

- intermediate;

- chutes.

Mainly due to the coarse-dispersed composition of bulk slag forming materials and ferroalloys, the release of these materials from the hoppers is not associated with great difficulties. However, due to the possible long residence time in the hoppers, relatively small portions of the sampling, the presence of a certain amount (up to 20%) of fines and dust, the material becomes jammed over the outlet openings with the formation of stable bridges and arches. To eliminate such jamming, it is necessary to shift the individual fragments of arches relative to each other. The solution to this problem can be provided with magnetic-impulse installations IM manufactured by RPE “MITEK” LLC. As a result of the high-speed movement of the hopper wall, shear stresses are generated in the layer of suspended material, that leads to its collapsing. This ensures an uninterrupted supply of bulk materials to the converter.

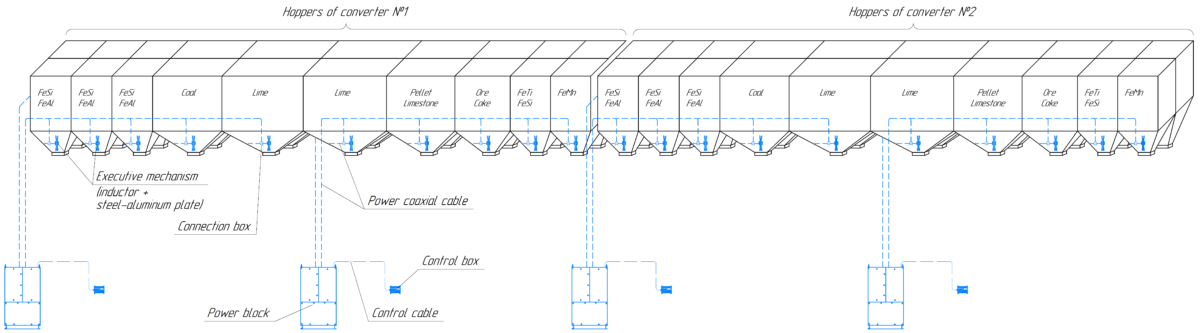

Example of application of the magnetic-impulse system of arches collapsing with the use of installations IM incorporated in the design solution of “Ukrgipromez” for the reconstruction of vertical paths for feeding materials into two converters and steel-pouring ladles of the converter workshop. The project provides for equipping all of 40 receiving hoppers of the converter workshop with four magnetic-impulse installations.

Scheme of equipping 20 hoppers of the converter workshop with a magnetic-impulse system of arches collapsing:

Works on the use of IM installations at other converter production facilities are under way (see the list of implementations).

Implementations map

Magnetic-impulse installations IM:

- ensure a sustainable release of material from equipped hoppers;

- clean the walls of hoppers from adhered material;

- provide efficient filter regeneration;

- operation in an energy-saving mode, operating costs are minimal;

- basically do not require reconstruction of hoppers when equipping them;

- do not violate the integrity of the walls of the hoppers;

- compatible with strain gauge systems for controlling the weight of material in hoppers;

- comply with the requirements of the Directives and harmonized technical regulation of the European Union on electrical safety and electromagnetic compatibility;

- applicable in hazardous areas of class 22, hazardous by ignition of combustible dust in accordance with the ATEX Directive;

- easily integrated into modern automated process control systems;

- reliable and durable (according to technical conditions – 10 years, in practice, some installations have already been in operation for more than 25 years).