An important link in the technological chain of the foundry is the manufacture of a casting mold from molding materials. In the general case, molding materials are sands, binding materials (clay, various resins, etc.), certain combinations of which provide such an important property of the molding mixture as plasticity, that is important for the manufacture of a high-quality casting mold. In turn, an increase in the plasticity of the molding mixture reduces its flowability, increases adhesion and, ultimately, contributes to the appearance of the mixture hanging in the hoppers used at various stages of the technological process of casting molds manufacture.

Depending on the casting method and the stage of manufacturing process of the casting mold, the following main types of hoppers used in foundry can be distinguished:

- cumulative of facing mixture;

- cumulative of filling mixture;

- cumulative of single mixture;

- mixture preparation;

- molding;

- knockouts;

- tillers (over runners);

- sand throwers;

- spills;

- dump.

All the molding mixtures loaded into these hoppers are more or less prone to bridging and sticking to the walls due to the presence of moisture in them, binding materials, that is aggravated by the operation of the mixture aging in the hopper required by the technology. Therefore, as a rule, the molding sands are not capable of free flowing out of the hoppers, that requires the use of any stimulators. Traditionally, electromechanical eccentric vibrators were used as such stimulators until recent times, that are mounted either directly on the wall of the hopper or on a vibrating sheet placed inside the hopper. However, vibrators have the following disadvantages:

- insufficient efficiency associated with the inability to destroy the adhesion of adhered molding mixture to the wall of the hopper due to the low speed of movement of the surface to be cleaned;

- low service life;

- possible destruction of the surface to be cleaned (hopper wall, vibrating sheet) in the places where vibrators are attached;

- the presence of spillage when using vibrating sheets.

The use of pneumatic collapsing in foundry hoppers is inefficient, since a jet of compressed air blows only a hole in the thickness of the molding mixture – a material with a plastic structure, and, moreover, does not destroy the adhesion of the stuck mixture to the hopper wall, and it can not contribute to the effective collapse of the suspended material in the hopper.

An alternative to electromechanical vibrators and pneumatic collapsing is the magnetic-impulse technology of arches collapsing and cleaning the walls of hoppers with molding sands on basis of IM installations manufactured by RPE “MITEK” LLC. As magnetic impulse installations are devoid of the inherent disadvantages of electromechanical vibrators and pneumatic coolapsing, they are successfully used in almost all types of foundry hoppers. Thus in 1991, at Rivne plant of tractor units, the installation IM5-0,8-8 was introduced at 4 hoppers for the preparation of molding sand. In 1992 year, at Kirovograd Foundry, two IM3-0,8-8 installations were introduced on 4 hoppers of burnt soil and 8 hoppers for the preparation of molding sand.

In the 1990s, 12 installations IM were introduced in the foundries of the Iron and Steel Works “Azovstal named after Ilyich” (see the list).

At all the above mentioned objects, the executive mechanisms of the installations are mounted directly on the walls of the hoppers (without vibrating sheets).

Examples of equipment schemes for installations IM of some production facilities

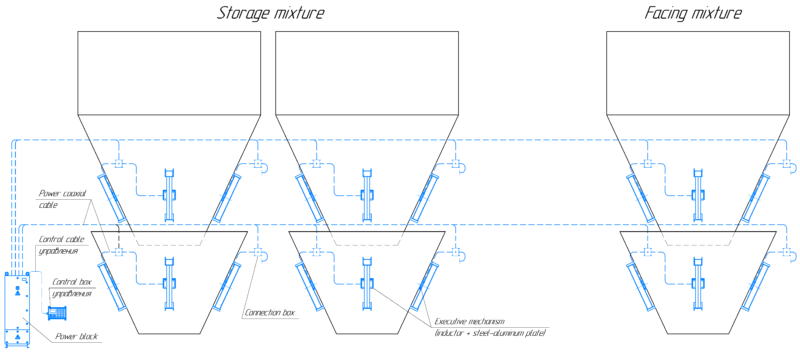

Scheme of equipping three storage hoppers with installation IM:

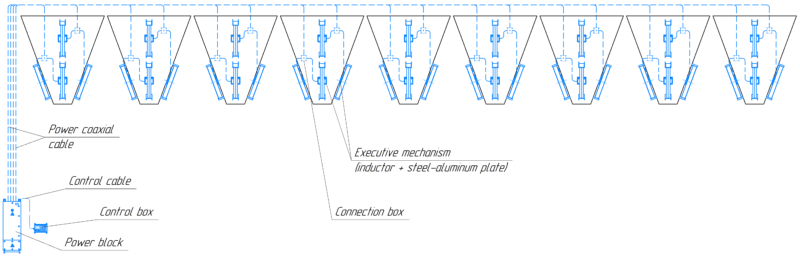

Example of equipping 9 hoppers with the installation above the runners of the mixing section of the shaped steel workshop:

The installations IM have also been introduced on the bag filters of the gas cleaning system of the foundry of the Iron and Steel Works “ArcelorMittal Kryvyi Rih”.

The use of magnetic-impulse installations IM on the hoppers of the foundry significantly increases the efficiency of the collapse of suspended masses, contributing to a more uniform release of material from the hoppers, reduces operating costs, preserves the integrity of the hoppers, increases the production culture, ensuring the reliable functioning of the collapsing system for a long period of operation.

Implementations map

Magnetic-impulse installations IM:

- ensure a sustainable release of material from equipped hoppers;

- clean the walls of hoppers from adhered material;

- provide efficient filter regeneration;

- operation in an energy-saving mode, operating costs are minimal;

- basically do not require reconstruction of hoppers when equipping them;

- do not violate the integrity of the walls of the hoppers;

- compatible with strain gauge systems for controlling the weight of material in hoppers;

- comply with the requirements of the Directives and harmonized technical regulation of the European Union on electrical safety and electromagnetic compatibility;

- applicable in hazardous areas of class 22, hazardous by ignition of combustible dust in accordance with the ATEX Directive;

- easily integrated into modern automated process control systems;

- reliable and durable (according to technical conditions – 10 years, in practice, some installations have already been in operation for more than 25 years).