Arches collapsing, elimination and prevention of bulk materials hanging in containers, as well as cleaning the walls of hoppers, silos, chutes and other objects from suspended, adhered, frozen materials is the main task assigned to the magnetic-impulse installations IM.

To solve this problem, the following algorithm of interaction with the Customer is optimal:

- analysis of the provided technical data on existing or projected facility that requires equipping with a magnetic-impulse cleaning system;

- development of technical solutions, including the determination of a specific type of IM installations by RPE “MITEK” LLC specialists, as well as number, design and location of attachment units for executive mechanisms at the facilities to be equipped;

- supply the Customer with a technical and commercial proposal for equipping facilities with IM installations;

- conclusion of a treaty for the supply of magnetic-impulse equipment and performance of contract supervision and commissioning;

- transfer of technical solutions to the Customer with detailed drawings and a list of materials that need to be prepared for mounting;

- manufacture of equipment (usually up to 60 calendar days);

- supply of equipment to the Customer;

- after the call for implementation – the arrival of specialists of RPE “MITEK” LLC to perform contract supervision and commissioning;

- training of staff, maintaining and operating the magnetic-impulse equipment;

- warranty service of the implemented installations IM.

In some cases, it is possible to organize the execution of mounting works on a turnkey basis, as well as organization of service maintenance under a separate contract.

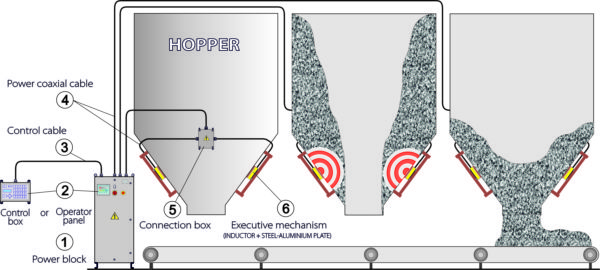

The magnetic-impulse installation IM consists of a power block, a control box, power and control cables, a set of connecttion boxes and executive mechanisms.

The principle of operation of the IM installation is based on the conversion of electrical energy accumulated in the power block into mechanical energy generated by the executive mechanism and aimed at collapsing of bulk material suspended in the hopper.

The high efficiency of the IM installations is attributed to a unique patented technical solution based on a non-contact method of impulse mechanical action on the surface to be cleaned, which is implemented by elements of the executive mechanisms of the magnetic-impulse installations IM.

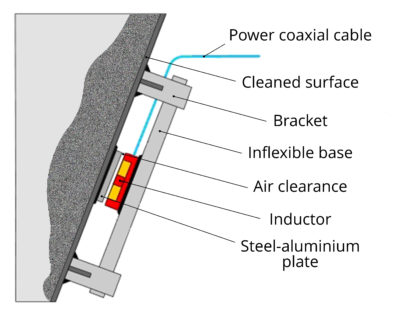

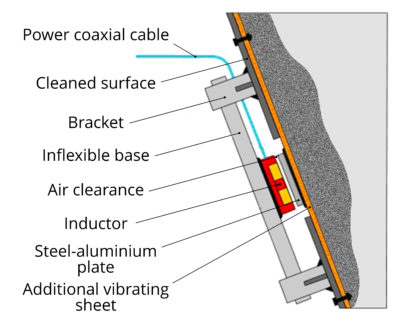

The main elements of the executive mechanism of magnetic-impulse installation IM are an inductor and a steel-aluminum plate. When the installation IM is turned on, the power block generates a powerful current impulse into the inductor winding and, according to the laws of electromagnetism, the inductor resting on a rigid base and a steel-aluminum plate rigidly attached to the surface to be cleaned repel each other.

As a result, the powerful impulse mechanical action on the surface to be cleaned, the so-called “electromagnetic sledgehammer”, is realized, and the surface is cleaned of adhering material. The strength of the mechanical impact and the number of generated impulses are regulated and selected sufficient to ensure collapsing of the suspended dust.

The specific type of installation IM for each object, and its cost accordingly, is determined based on the number and size of serviced hoppers, material properties in hoppers, hopper design, etc., and is usually determined and agreed upon after examination of these objects by our specialists.

To ensure the maximum efficiency of elimination and prevention of bulk materials hanging in hoppers with a capacity of over 200 tons, thick-walled, lined with armoured plates, with rigid ribbing and hard bulk material, before the introduction of the magnetic-impulse installation IM, it may be necessary to reconstruct them, providing for the mounting of vibrating sheets in the required zone made of abrasive resistant steel, fixed in a certain way, to which an impulsed mechanical action will be made by the executive mechanisms of the magnetic-impulse installation IM.

There are various options for the design of fasteners and the placement of executive mechanisms on the surfaces to be cleaned. The choice depends on the capacity and design of the object to be equipped, the thickness of the surfaces to be cleaned, the presence of stiffening ribs, the physicochemical properties of the loaded bulk material, etc.

In view of the wide variety of objects equipped with IM devices, an individual approach to each of them is required in order to determine the parameters of the acting mechanical impulses required for efficient cleaning and the number of executive mechanisms installed on the object.

Therefore, magnetic-impulse installations IM manufactured by RPE “MITEK” LLC are produced in various modifications, distinguished by energy parameters and number of channels, respectively, and number of executive mechanisms.

The specialists of RPE “MITEK” LLC analyze the technical data provided by the Customer and develop technical solutions that are optimal for solving specific particular problems of collapsing and inducing the evacuation of suspended bulk material. This approach ensures the maximum efficiency of using the magnetic-impulse equipment we offer.

The implementation of IM installations is carried out under the guidance of engineers of our enterprise, performing contract supervision and commissioning. The organization and execution of mounting works is provided by the Customer.

The structures of the executive mechanisms attachments are manufactured by the Customer in accordance with the design solutions produced by the design and research service of RPE “MITEK” LLC.

In some cases, it is possible to implement magnetic-impulse installations IM on a turnkey basis, i.e. organization of installation work by the specialists of our company.

After the introduction of installations IM, training is carried out for staff supposed to maintain and operate the introduced magnetic-impulse equipment.

In the “Scope of application” section, you will find detailed information on the practice of IM installations use at production facilities with photo and video materials.