In the ferrous and non-ferrous metallurgy, chemical and oil industries, in the production of construction materials, as well as in the food, textile and other industries, various dust collection and gas cleaning systems based on bag and electric precipitators are widely used. Their purpose is to separate dust from gases and air.

In the ferrous and non-ferrous metallurgy, chemical and oil industries, in the production of construction materials, as well as in the food, textile and other industries, various dust collection and gas cleaning systems based on bag and electric precipitators are widely used. Their purpose is to separate dust from gases and air.

The following problems are very common in gas cleaning systems:

- accumulation of dust on the houses of bag filters and on the electrodes of electric precipitators, requiring the use of appropriate technological operations for its removal in order to regenerate the filters;

- hanging of the filtered dust in the dust collection hoppers located directly under the filters, as well as in the storage hoppers of the dust unloading areas.

These factors negatively affect both the production process and environmental performance.

Various systems for shaking hoses and electrodes are used to regenerate the filters.

Traditional shaking systems are:

- mechanical system for electric and bag filters – is a complex mechanism in operation, consisting of shafts, worm gears, cams, couplings, levers, etc., in most cases, it does not allow to quickly adjust the force and frequency of impact on the treated bags and electrodes;

- pneumatic impulse system for bag filters. This system requires the generation of high pressure air and its special preparation (for example, drying).

To eliminate the hanging of filtered materials in hoppers, mechanical agitators, electric vibrators, pneumatic hammers, and pneumatic guns are traditionally used. In most cases, these systems are insufficiently effective, do not provide cleaning of the inner surfaces of the hoppers from adhered materials, and have significant operating costs.

An effective tool for solving the problems of freezing and sticking of bulk materials are developed and manufactured by RPE “MITEK” LLC magnetic-pulse installations IM, which over the past decades have found wide application in various industries to eliminate freezing and sticking of bulk materials such as ore, charge, coal rock, limestone, cement, compound feed, flour, other materials, including filtered dust.

The Installations IM are successfully used in gas cleaning systems both for eliminating dust hanging in various hoppers and cyclones, and for shaking the hoses and electrodes of bag and electric precipitators in order to regenerate them.

The installations IM are more efficient and economical in operation compared to the above-mentioned traditional shaking and cleaning systems due to the following factors:

- the use of energy-saving technology;

- the ability to quickly adjust the amplitude, shape, repetition rate of the impacting impulses;

- high efficiency, reliability and ease of maintenance;

- maintainability and durability – service life of IM installations before overhaul is at least 10 years.

Magnetic- impulse regeneration of bag filters

We call your attention to a technical solution patented by the specialists of RPE “MITEK” LLC (Patent of Ukraine #133300).

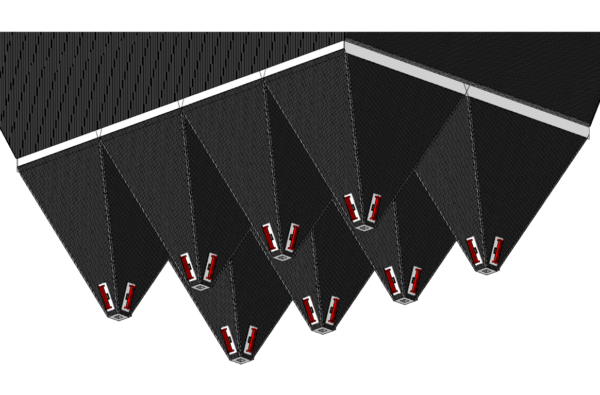

To regenerate the bag filter, the power block generates a powerful current impulse into the inductor winding, and a force arises that pushes the inductor away from the steel-aluminum plate. The steel-aluminum plate is repelled from the stationary inductor and sets in motion the traverse with the arms suspended from it. As a result of this action, the hoses are stretched “in the impulse mode”, and after the return of the traverse to its original position, they take their initial state. At the same time, dust particles are released from the fabric and, under the action of gravity, fall into the hopper.

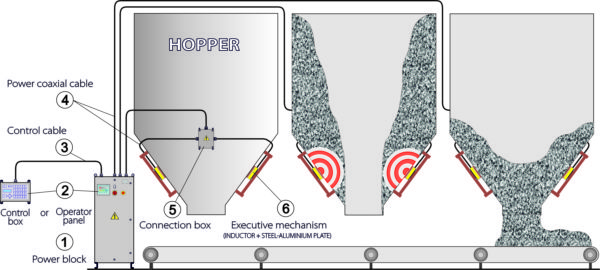

Scheme of equipping a bag filter with a magnetic-impulse regeneration system based on the IM installation:

Examples of application of installations IM for regeneration of hoses of bag filters

The first completed project was the introduction in 2005 at ArcelorMittal Kryvyi Rih of bag filters manufactured by Dneproenergostal LLC (Zaporozhye), equipped with regeneration systems based on installatios IM, namely:

- in the shaped steel molding workshop of the combine – two filters of the FV-45 type, equipped with two installations IM2-1,2-3;

- in the refractory lime shop – the FREMIR-90 filter, equipped with the IM3-0,8-6 installation.

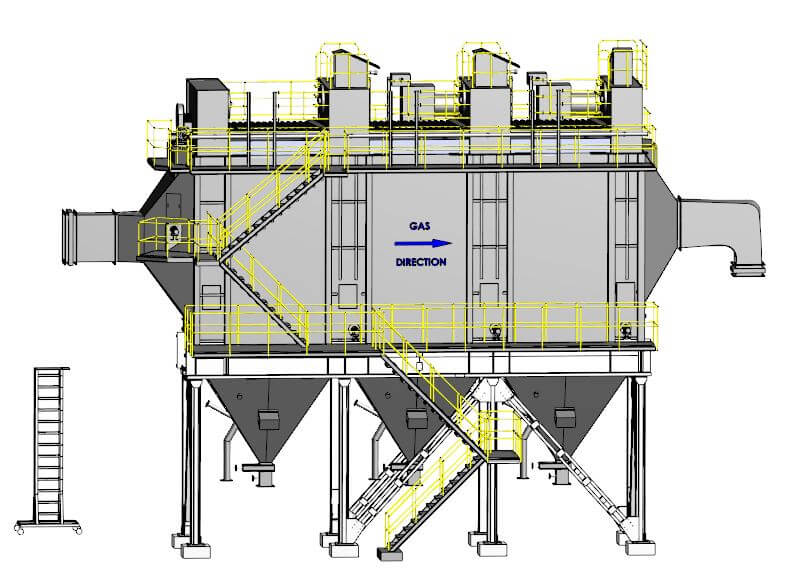

In 2008, IM3-1.2-12 installation was implemented at Crimea TITAN (Armiansk), designed to shake the hoses of a twelve-section RFG-V filter in the SKA and ZhS workshop.

The installation replaced the previously existing mechanical shaking system provided by the RFG-V filter manufacturer. Operational practice has shown a higher efficiency of the installation in comparison with a mechanical regeneration system, as well as its ease of maintenance.

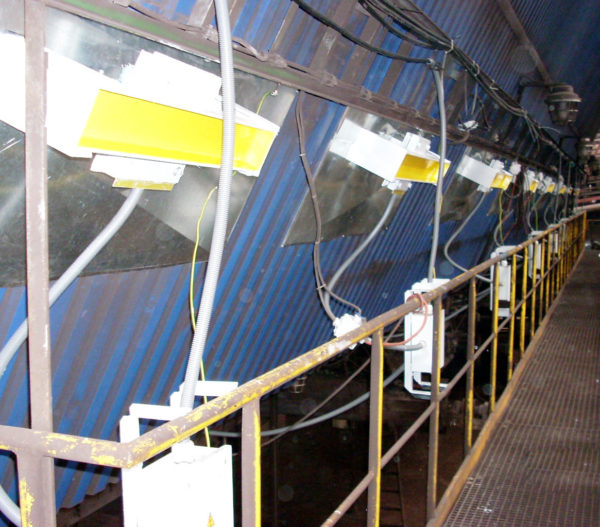

The photo (right) shows the appearance of the RFG-V bag filter equipped with a magnetic-impulse regeneration system based on IM3-1,2-12 installation.

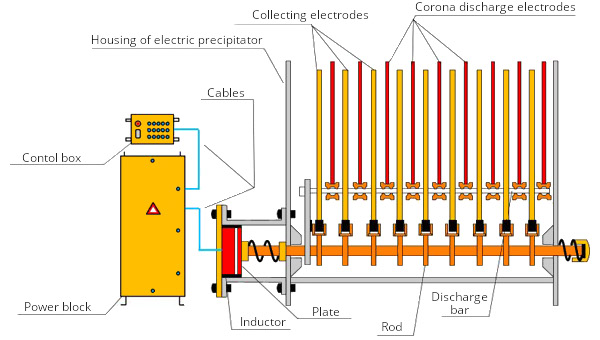

Magnetic-impulse regeneration of electric precipitator

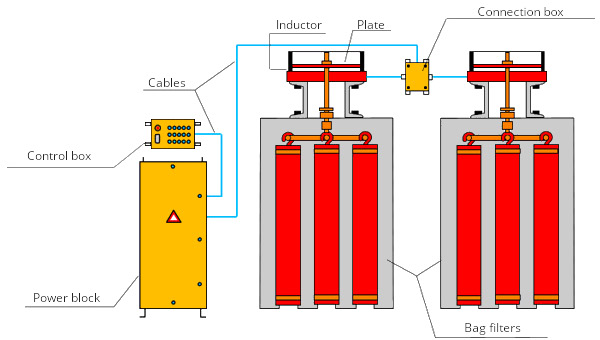

Electric precipitator regeneration system based on the IM installation:

There is a technical solution for the regeneration of an electric precipitator patented by the specialists of RPE “MITEK” LLC (Patent of Ukraine #37190).

To regenerate the electric precipitator, the power block generates a powerful current impulse into the winding of the stationary inductor. In this case, a force arises that pushes the steel-aluminum plate away from the inductor and leads to a longitudinal movement of the thrust. The nozzles available on the rods impact on the collecting electrodes, and the bar attached to the rod in a special way impacts on the corona-discharge electrodes, that leads to cleaning the surface of the electrodes from dust deposited on them.

At the moment, there are no industrial implementations of IM installations for the regeneration of electric precipitators, despite a successful technical solution. The project on the use of magnetic-impulse installations IM for regeneration of electric precipitators is in the process of being finalized and improved. At the same time, there are positive results of experimental and industrial operation of an experimental model of a system based on the IM installation at one of the electric precipitators of the Tripolye TPP.

At your request, we are ready to offer the development of designs for electrode shaking systems based on IM installations with reference to specific electric precipitators. We invite all the interested parties to cooperate on this topic.

Freezing elimination in silos with filtered material

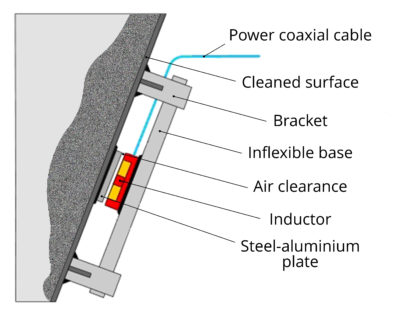

The magnetic-impulse installation IM consists of a power block, a control box, power and control cables, a set of connection boxes and executive mechanisms.

The principle of operation of the IM installation is based on the conversion of electrical energy accumulated in the power block into mechanical energy generated by the executive mechanism and aimed at the collapsing of dust suspended in the hopper.

The main elements of the executive mechanism of magnetic-impulse installation IM are an inductor and a steel-aluminum plate. When the installation is turned on, the power block generates a powerful current impulse into the inductor winding and, according to the laws of electromagnetism, the inductor resting on a rigid base and a steel-aluminum plate rigidly attached to the surface to be cleaned repel each other.

As a result, a powerful impulse mechanical action on the surface to be cleaned, the so-called “electromagnetic sledgehammer”, is realized, and the surface is cleaned of adhering material. The strength of the mechanical impact and the number of generated impulses are regulated and selected sufficient to ensure the collapsing of the suspended dust.

Due to the wide variety of objects equipped by IM devices, an individual approach to each of them is required in order to determine the parameters of the acting mechanical impulses necessary for effective cleaning and the number of executive mechanisms mounted on the object.

Therefore, magnetic-impulse installations IM manufactured by RPE “MITEK” LLC are produced in various modifications, distinguished by energy parameters and the number of channels, respectively, and the number of executive mechanisms.

Examples of application of IM installations to eliminate dust hanging in hoppers

The first organization to use the IM installation to eliminate the hanging of filtered dust in the storage hoppers of the dust offloading areas was Ukrgipromez (Dnepropetrovsk), with which the following projects were implemented:

- section “ladle furnace” JSC “Donetsk Metallurgical Plant” – IM3-0,8-4 – 2003;

- blast furnace shop of JSC Zaporizhstal – IM3-0,8-4 – 2004;

- blast-furnace shop (DP #6) OJSC “Azovstal” – IM5-0,8-5 – 2003.

It should be noted the equipping of such objects as:

- a dust collector for an electric precipitator at the metallurgical plant of ZAO ISD Dunaferr (Hungary);

- bag filter hoppers at the Georgian Manganesi ferroalloy plant (Georgia);

- dust collection tower in the blast-furnace shop of the ArcelorMittal Ostrava metallurgical plant (Czech Republic);

- dust collection hopper for Yugtsement electric precipitator Dyckerhoff Cement Ukraine;

- dust collection hoppers for electric precipitators #4, #5, #6 AC-2 of PJSC “ArcelorMittal Kryvyi Rih”.

It is worth noting the equipping of the dust collection tower in the blast furnace workshop and dust collection hoppers under electric precipitators in the sinter production of the metallurgical combine “U.S. Steel, s.r.o. Kosice” (Slovakia):

Thus, on the electric precipitators, the standard systems for hanging elimination (pneumatic hammers) of the European manufacturer of electric precipitators were replaced with IM installations. As a result, the suspended dust was eliminated, the walls of the hoppers are constantly kept in a clean condition, and the result of a significant improvement in the readings of gas cleaning produced by filters equipped with IM installations compared to filters equipped with pneumatic hammers was obtained.

Below is the same hopper before and after the application of the magnetic-impulse installation IM:

We suggest you to learn about the list of IM installations at various dust collection objects and gas cleaning systems.

The research and development service of RPE “MITEK” LLC maintains a constant process of developing new technical solutions in the field of magnetic-impulse technologies, which are also used in the implementation of IM installations in gas cleaning systems.

We are always glad to receive your orders!

Implementations map

Magnetic-impulse installations IM:

- ensure a sustainable release of material from equipped hoppers;

- clean the walls of hoppers from adhered material;

- provide efficient filter regeneration;

- operation in an energy-saving mode, operating costs are minimal;

- basically do not require reconstruction of hoppers when equipping them;

- do not violate the integrity of the walls of the hoppers;

- compatible with strain gauge systems for controlling the weight of material in hoppers;

- comply with the requirements of the Directives and harmonized technical regulation of the European Union on electrical safety and electromagnetic compatibility;

- applicable in hazardous areas of class 22, hazardous by ignition of combustible dust in accordance with the ATEX Directive;

- easily integrated into modern automated process control systems;

- reliable and durable (according to technical conditions – 10 years, in practice, some installations have already been in operation for more than 25 years).