The main products are magnetic-impulse installations IM of various modifications.

RPE “MITEK” LLC is capable of performing the whole range of works when equipping the objects with IM installations:

- development of design solutions and design documentation;

- manufacturing and delivery of IM installations;

- reconstruction of objects in order to prepare them for equipping with IM

installations; - mounting (contract supervision) of IM installations at the objects to be equipped;

- commissioning of IM installations;

- training of the Customer’s personnel;

- warranty and post-warranty (service) maintenance of the implemented IM installations.

Under agreement with the Customer, RPE “MITEK” LLC can equip facilities on a turnkey basis, or perform individual works from the above list.

The main products are magnetic-impulse installations IM of various modifications.

RPE “MITEK” LLC is capable of performing the whole range of works when equipping the objects with IM installations:

- development of design solutions and design documentation;

- manufacturing and delivery of IM installations;

- reconstruction of objects in order to prepare them for equipping with IM

installations; - mounting (contract supervision) of IM installations at the objects to be equipped;

- commissioning of IM installations;

- training of the Customer’s personnel;

- warranty and post-warranty (service) maintenance of the implemented IM installations.

Under agreement with the Customer, RPE “MITEK” LLC can equip facilities on a turnkey basis, or perform individual works from the above list.

Appointment

Magnetic-impulse installations IM, are designed for:

- prevention and elimination of freezing of materials in hoppers;

- cleaning the walls of hoppers, silos, various cargo handling devices and other surfaces from suspended, adhered, frozen bulk materials;

- cleaning the inner surfaces of railway cars from adhered, frozen bulk materials both during bottom unloading of railway cars and during their unloading on car dumpers;

- shaking the hoses of the bag collectors for the purpose of their regeneration;

- other.

Operating principle

The power block generates a powerful current impulse into the inductor winding. The magnetic field of the inductor created by this current induces a current impulse in the steel-aluminum plate mounted with a gap in relation to the inductor and rigidly fixed to the outer side of the surface to be cleaned.

As a result of the interaction of impulse currents flowing through the winding of the inductor and induced in the plate, the inductor and the plate repel one another, and a non-contact impulse mechanical effect on the surface to be cleaned is produced.

Local elastic deformation occurs in the surface to be cleaned, and shear stress appears in the thickness of the adhered material.

The combined action of these processes violates the integrity of the layer of adhered material, destroys the adhesion of the material to the surface to be cleaned and leads to its cleaning.

The strength of the mechanical action and the number of impulses are regulated and selected sufficient to ensure the collapse of adhered materials.

When cleaning the surface (hopper wall), a series of impulses is consequently flown to each involved channel of the installation IM (a pair of executive mechanisms), the number of impulses in the series and the interval between them are adjustable, usually 3÷6 impulses in the series with an interval of 3÷8 seconds between impulses.

After consequent flowing of a series of impulses to all the channels involved, the installation IM goes into standby mode. The next flow of impulses to the executive mechanisms occurs according to the set mode of operation (either from the operator’s signal, or from the sensor signal, or according to the prescribed program).

Areas of application

IM installations are used in all fields where storage, transportation and processing of bulk materials are employed.

To get acquainted with the practice of application and examples of equipping the various objects with IM installations, we suggest choosing the section of interest.

Select area of application:

Mining and processing

Materials intended for collapsing:

Ore, coal, limestone, mining mass, rock, concentrates, salts, potassium chloride, bentonite, pellets, charge, filtered materials, dust, etc.Objects intended for equipping:

Receiving hoppers, hoppers under railcar dumpers, accumulating and storage hoppers, dosing hoppers, surge plates and loading chutes, cargo handling units, final product hoppers, unloading hoppers, overflow chutes, etc.

Electric power and fuel

Materials intended for collapsing:

Coal, coke, ash, chalk, pellets, etc.Objects intended for equipping:

Receiving, accumulating, dosing, expendable hoppers, storage silos, cyclones, dust collecting towers, fluidized bed installations, chutes and pipes, car dumpers.

Metallurgy

Materials intended for collapsing:

Charge, ore, limestone, lime, bauxite, coal, coke, bentonite, flux, molding sands, ferroalloys, sand, dust, etc.Objects intended for equipping:

Receiving, charge, intermediate, storage, waste, expendable hoppers, dosing section hoppers, hoppers under railcar dumpers, storage silos, sintering machine hoppers, crushing section hoppers, mixer drum hoppers, raw material hoppers, overflow chutes, pipe chutes, sintering machine unloading trays, surge plates, prechambers, dust collecting towers, dust pipelines, dust collection hoppers, mixture preparation hoppers, molding hoppers, knockouts, thermosyphon blocks, etc.

Chemical industry

Materials intended for collapsing:

Ore, lump sulfur, titanium dioxide, phosphogypsum and phosphogypsum hemihydrate, apatite concentrate, soda, salts, superphosphates, coal, coke, zinc oxide, complex mineral fertilizers, sylvinite, potassium chloride, granulated blast-furnace slag, bulk additives, aluminum fluoride trihydrate, busite, ammonium sulfate, granulated slag, filtered materials, dust, etc.Objects intended for equipping:

Receiving, accumulating, expendable hoppers, silos, cyclones, cargo handling units and chutes, adsorbers, hoppers with bulk additives, fluidized bed installations, Allgaer dryers, hoppers for microgrinding and packaging, hoppers for final products, unloading units, etc.

Production of construction materials

Materials intended for collapsing:

Rock, crushed stone, sand, gypsum, slag, chalk, limestone, lime, cement, clinker, cinders, clay, aleurolite, dust, etc.Objects intended for equipping:

Receiving, raw, accumulating, consumable hoppers, silos, cyclones, chutes, pipes, unloading units, etc.

Food industry

Materials intended for collapsing:

Flour, milk powder, sugar, bran, starch, dry whey, ash, bone meal, cake, husks, meal, compound feed, etc.Objects intended for equipping:

Production hoppers, flour bulk storage silos, drying towers, cyclones, flour trucks, filtered material collection hoppers, dosing hoppers, etc.

Gas cleaning

Materials intended for collapsing:

Dust, ash, etc.Objects intended for equipping:

Dust collection hoppers, bag filters, prechambers, electric precipitators, dust collecting towers and cyclones, adsorbers, overflow chutes, storage hoppers of dust dumping area, thermosyphon blocks, etc.

Coal

Materials intended for collapsing:

Run-of-mine coal, coke, anthracite, pulverized coal,coal of various grades, etc.Objects intended for equipping:

Receiving, accumulating, intermediate, dosing, expendable hoppers, coal storage silos, hoppers under railcar dumpers, screening hoppers, cargo handling units and chutes, railcar dumpers, pulverized coal injection systems, dust collecting towers and cyclones, hopperer racks, etc.

Description and characteristics

Composition

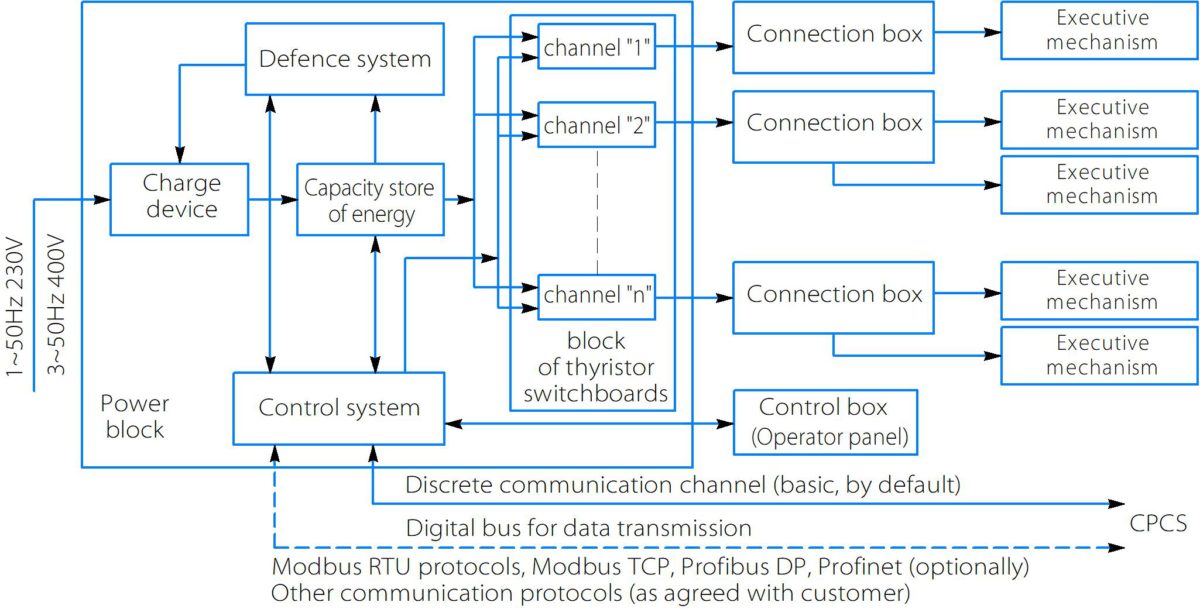

The power block is designed to generate the powerful current impulses. It is assembled in a dust- and moisture-proof cabinet and consists of a charger, a capacitive energy storage, a block of thyristor switches, control and protection systems. The power block is multichannel while one or two executive mechanisms can be connected to each channel through connection boxes and a power coaxial cable.

The executive mechanism consists of an inductor and a steel-aluminum or steel-copper plate. The control box is connected to the power block using a control cable.

Block diagram of the IM installation:

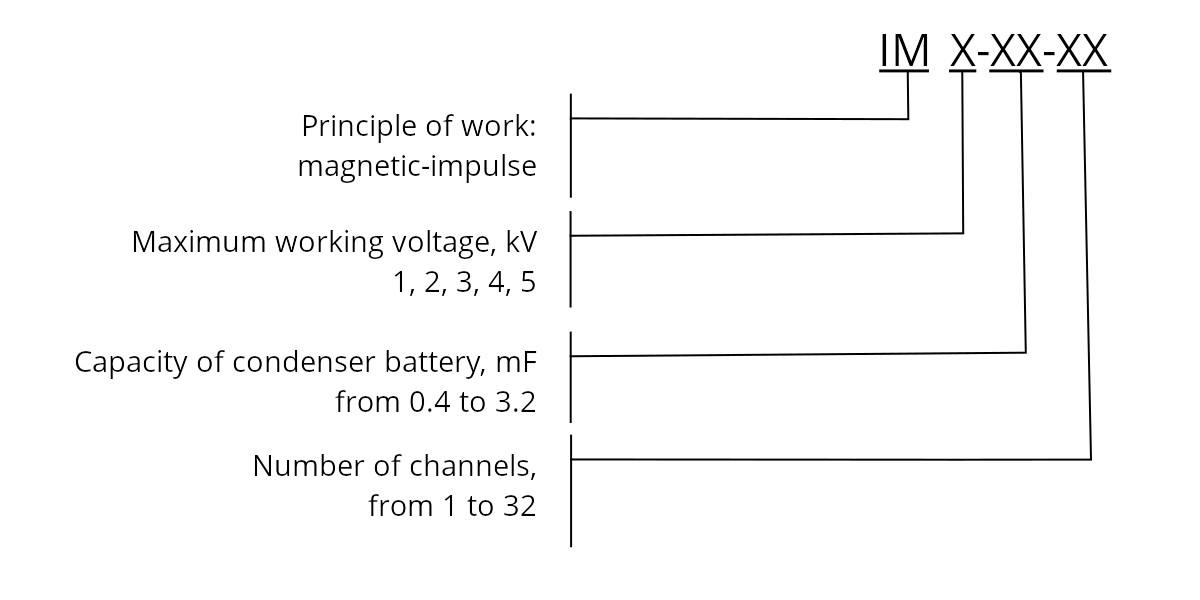

Structure and designation

IM installations are divided into types according to the maximum operating voltage:

- IM1 – up to 1000V,

- IM2 – up to 2000V,

- IM3 – up to 3000V,

- IM4 – up to 4000V,

- IM5 – up to 5000V.

IM installations are produced with different energy characteristics, which determine the maximum possible value of mechanical impulse action on the surface to be cleaned, and with a different number of channels (from one to thirty-two), defining the number of impulse action points implemented by one installation.

The structure of the symbolic notation of the types of IM installations is shown in the following figure:

Example of designation:

IM3-1,5-10 is an installation with a maximum operating voltage of 3 kV, the condenser bank capacity of 1.5 mF, and the number of channels is 10.

Technical specifications

The main technical characteristics of IM installations, according to ТУ У3.01-19289902-170-98, are as follows::

| Parameter name | Type of installation | ||

| IM1, IM2 | IM3 | IM4, IM5 | |

| Supply voltage, V ±10% | 230 | 400 | 400 |

| Power supply frequency, Hz ±1% | 50 | 50 | 50 |

| Installed capacity, kVA | from 0.5 to 1.6 | from 1.6 to 4.0 | from 2.5 to 4.0 |

| Maximum operating voltage, kV | от 1 to 2 | 3 | from 4 to 5 |

| Condenser bank capacity, mF | from 0.4 to 3.2 | from 0.4 to 2.4 | from 0.4 to 2.4 |

| Number of channels | from 1 to 32 | from 1 to 24 | from 1 to 24 |

| Number of executive mechanisms in the channel | 1 or 2 | 1 or 2 | 1 or 2 |

| Max stored energy, kJ | from 0.2 to 6.4 | from 1.8 to 10.8 | from 3.2 to 30 |

| Impulse repetition interval, s, no more | 10 | 10 | 10 |

| Degree of protection | IP54 and more | ||

| Operation mode | Manual and/or automatic with integration into the APC system | ||

Note: Taking into account the peculiarities of the Customer’s objects to be equipped, the parameters of the magnetic-impulse installations can differ from those ones indicated in the table.

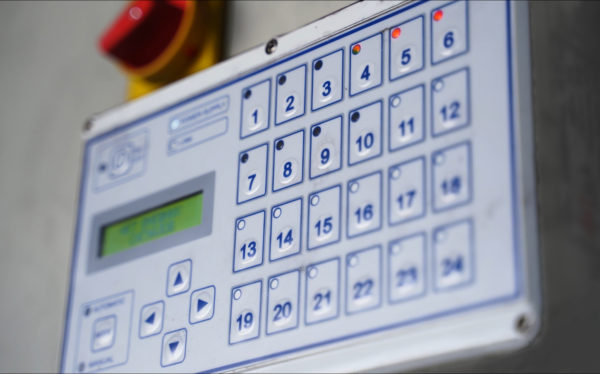

Automation

The control systems of our equipment, which have been improved over a period of several decades, provide optimal simplicity of IM installations use and high-definition of data, ensuring the maximum efficiency of collapsing and cleaning.

The control systems of our equipment, which have been improved over a period of several decades, provide optimal simplicity of IM installations use and high-definition of data, ensuring the maximum efficiency of collapsing and cleaning.

A flexible control system allows to operate IM installations in:

- manual mode,

- remote control mode,

- fully automatic mode.

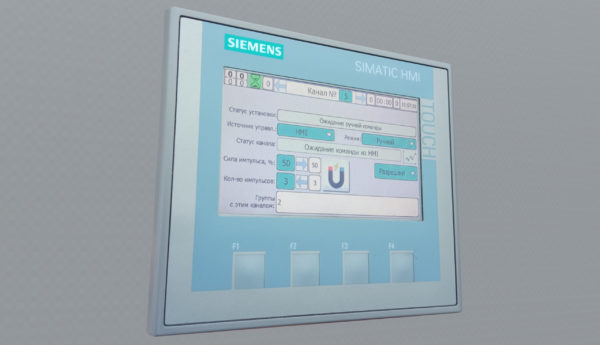

The architecture of the control system is a structure built on the basis of flexibly expandable system modules. The integrated modular solution allows easy scalability of the control system for different types of installations and application tasks.

Intuitive operation with a display, quick access buttons and full-color indicator lights providing clear visualization of operating states of IM installation using graphic symbols, combined with modern touchscreen displays, increases the availability of the IM installation and creates space for greater control flexibility.

Maximum operational reliability as well as operational safety are ensured by the monitoring and protection functions integrated into the control system. There are also control functions and protection against accidental or deliberate errors in the course of controlling, that allows to minimize the so-called human factor.

Simple connection to the upper-level visualization and control systems, condition monitoring to ensure a consistently high efficiency of the system are implemented already in the basic configuration using discrete communication channels. If the customer wishes to expand the communication capabilities of the IM installation, it is equipped with digital communication channels, and it is possible to use such popular communication protocols as Modbus RTU, Modbus TCP, Profibus DP, Profinet, that allows for a simple and flexible integration of the IM installations into the automatic network of a modern high-tech enterprise.

Simple connection to the upper-level visualization and control systems, condition monitoring to ensure a consistently high efficiency of the system are implemented already in the basic configuration using discrete communication channels. If the customer wishes to expand the communication capabilities of the IM installation, it is equipped with digital communication channels, and it is possible to use such popular communication protocols as Modbus RTU, Modbus TCP, Profibus DP, Profinet, that allows for a simple and flexible integration of the IM installations into the automatic network of a modern high-tech enterprise.

If the customer needs other communication protocols, we will discuss with interest and readiness the details of a technical and economic solution to such a problem.

Advantages

The main advantages of IM installations in comparison with magnetic-impulse installations of other manufacturers:

- The presence in the executive mechanisms of a secured gap between the inductor and a steel-aluminum plate rigidly fixed on the surface to be cleaned. Due to this design, “MITEK” patented method of completely contactless action on the surface to be cleaned with a special form of power impulse, which provides both high efficiency of prevention of bridging and surface cleaning, as well as the reliability and durability of IM installations.

- The existence of types of IM installations with a maximum stored energy of up to 30 kJ, which makes it possible to use IM installations at complex objects – hoppers with a capacity of 200 tons or more, thick-walled, lined, with rigid ribbing and difficult-to-flow material. MITEK has manufactured and implemented about 100 installations with a maximum stored energy of more than 14 kJ and an operating voltage of 4 kV and above. The use of magnetic impulse installations with lower energy indicators may not provide a sufficient effect of bridging on the above complex objects.

Documentation

| Reviews | ||

| • | NKGOK (ArcelorMittal Krivoy Rog) #1 | Sinter workshops #1, #2, #3 of mining and processing enterprise |

| • | ArcelorMittal Kryvyi Rih | Refractory-lime workshop on bag filter FREMIR-90 |

| • | ArcelorMittal Kryvyi Rih | Production Hoppers of the sinter workshop of metallurgical |

| • | DMC | Sinter workshop #2 |

| • | Azovstal #5 | Blast furnace workshop, sinter workshop, foundry workshop |

| • | Daltransugol | Feeder hoppers of railcar dumper |

| • | Kazzinc Riddersky GOK | Collapsing of the arches of raw materials inside two hoppers of technogenic ore |

| • | Mnogovershinnoye | Receiving hopper of crushed ore |

| • | Mykolaiv alumina refinery (Rusal) | Wet grinding section for cleaning from bauxite sticking |

| • | Mykolaiv alumina refinery (Rusal) | Wet grinding section for cleaning from bauxite sticking 2 |

| • | Novo-Irkutskaya CHP | Hoppers of railcar dumper |

| • | Pikalevskaya soda | Cleaning of the discharge metallic hoppers of electrostatic precipitator of the clinker roasting |

| • | OGOK POLYUS | Collapsing of the arches of raw materials in four receiving hoppers of crushed ore |

| • | Valunisty Mine | Collapse of the arches of raw materials in four storage hoppers of crushed ore |

| • | Valunisty Mine, 10 months of operation | Efficiency of the IM installation for 10 months of operation |

| • | Thermoanthracite | Collapse of coal in the storage hopper in screening tank of the cargo handling station |

| • | Cement LLC (Review) | Coal dust hopper, gypsum hopper and slag hopper |

| • | Dyckerhoff Yug-Tsement | Chute of coal dust hopper |

| Economic efficiency of IM installations | Reviews of economic efficiency during the use of magnetic- impulse installations IM | |

| • | ArcelorMittal Kryvyi Rih GOK | Sinter workshop #2 (planned calculation) |

| • | ArcelorMittal Kryvyi Rih GOK | Sinter workshop #1 |

| • | ArcelorMittal Kryvyi Rih | Sinter workshop MP (planned calculation) |

| • | ArcelorMittal Kryvyi Rih | Sinter workshop No1 (planned calculation) |

| • | DMC | Sinter workshop No2 (planned calculation) |

| • | DMC | Sinter workshop No2 (actual economic effect) |

| • | Alchevsk Iron and Steel Works | Sinter workshop |

| Full implementation lists | |

| • | Full list |

| • | Industrial production |

| • | Food production |

| Patents | ||

| • | Utility model patent (Germany) | Utility model patent #212019000226 |

| • | Utility model patent #196679 (RF) | Utility model patent "Device for cleaning surfaces from various kinds of deposits" |

| • | Patent for invention #2153403 (RF) | Patent for invention "Method for cleaning surfaces from various kinds of deposits and device for its implementation" |

| • | Utility model patent #133300 | A patent for a useful model "Device for cleaning surfaces from various kinds of deposits" |

| • | Invention patent #86639 | Patent "Method and device for cleaning the wall from deposits (options)" |

| • | Utility model patent #86666 | Patent "Device for clearing of adhered or frozen bulk cargoes of internal surfaces of open-top railcars on rotary railcar transfer" |

| • | Utility model patent #86670 | Patent "Device for cleaning the internal surfaces of railway cars from adhered or frozen bulk materials" |

| • | Invention patent #90023 | Patent "Regeneration device of electrodes of electric precipitator" |

| • | Invention patent #90172 | Patent "Regeneration device of a bag filter" |

| • | Invention patent #100621 | Patent "The way of cleaning the internal surfaces of railway cars" |

| • | Invention patent #100622 | Patent "Device for cleaning the inner surfaces of open-top railcars on a rotary railcar transfer" |

| • | Invention patent #100623 | Patent "Device for cleaning the inner surfaces of railway cars from stuck or frozen bulk material" |

| • | Patent of the invention #101691 | Patent "Method of cleaning the inner surface of hoppers with stiffening ribs from various kinds of deposits" |

| • | Patent of the invention #101692 | Patent "Hopper" |

| Certificates | ||

| • | Certificate СЄ | Certificate of compliance with the Directives of the European Parliament and of the Council on electrical safety and electromagnetic compatibility. |

| • | Hygienic certificate SES | Certificate of compliance with the requirements of the Ministry of Health of Ukraine of the State Sanitary and Epidemiological Service. |

| • | Certificate of conformity ISO9001:2015 | Certificate of conformity of the enterprise quality management system to the requirements of the international standard ISO9001: 2015. |

| Declarations | ||

| • | Declaration of compliance with technical regulations of Ukraine | Declaration of compliance with the "Technical regulations for the safety of low-voltage electrical equipment" and the "Technical regulations for electromagnetic compatibility of equipment" of Ukraine |

| • | Declaration of Conformity to the Technical Regulations of the Eurasian Economic Union (EAEU) | Declaration of compliance of IM installations with the requirements of the technical regulations of the Eurasian Economic Union (EAEU): "On the safety of low-voltage equipment", "Electromagnetic compatibility of technical means" |

| • | EU Declaration of Conformity to the ATEX Directive | Declaration of compliance of IM installations with the requirements of the European Union in accordance with the ATEX Directive 2014/34/EU for use in areas with hazardous combustion dust |

| • | Declaration of compliance of the MTB with labor protection issues | Declaration of compliance of the employer's material and technical base with the requirements of the legislation on labor protection and industrial safety |

| Permissions | ||

| • | Permission of StateCityIndsupervision of Ukraine for use | Permission of StateCityIndsupervision of Ukraine for operation of IM installations in explosive zones. |

| • | Permission of StateCityIndsupervision of Ukraine for dangerous works | Permission of StateCityIndsupervision of Ukraine for performance of works and operation of the equipment of increased danger. |

| Licenses and certificates | ||

| • | License of SACI of Ukraine | License of the State Architectural and Construction Inspectorate of Ukraine to perform design, mounting and commissioning works |

| • | Certificate for the MITEK trademark | "Certificate of Mark for Goods and Services" |

| Policies | ||

| • | Quality policy | Quality policy of RPE “MITEK” LLC ISO 9001:2015 |

| • | Privacy policy on the site | Agreement on the confidentiality of the use of users data of the site mitek.com.ua |

| Advertising documentation | ||

| • | Promotional leaflet | Promotional leaflet of RPE “MITEK” LLC |

| • | Catalogue of installations IM | The catalog describes the technical characteristics, types, principle of operation of the magnetic-impulse installations IM |